RUSSELLVILLE, MO | Since 2010

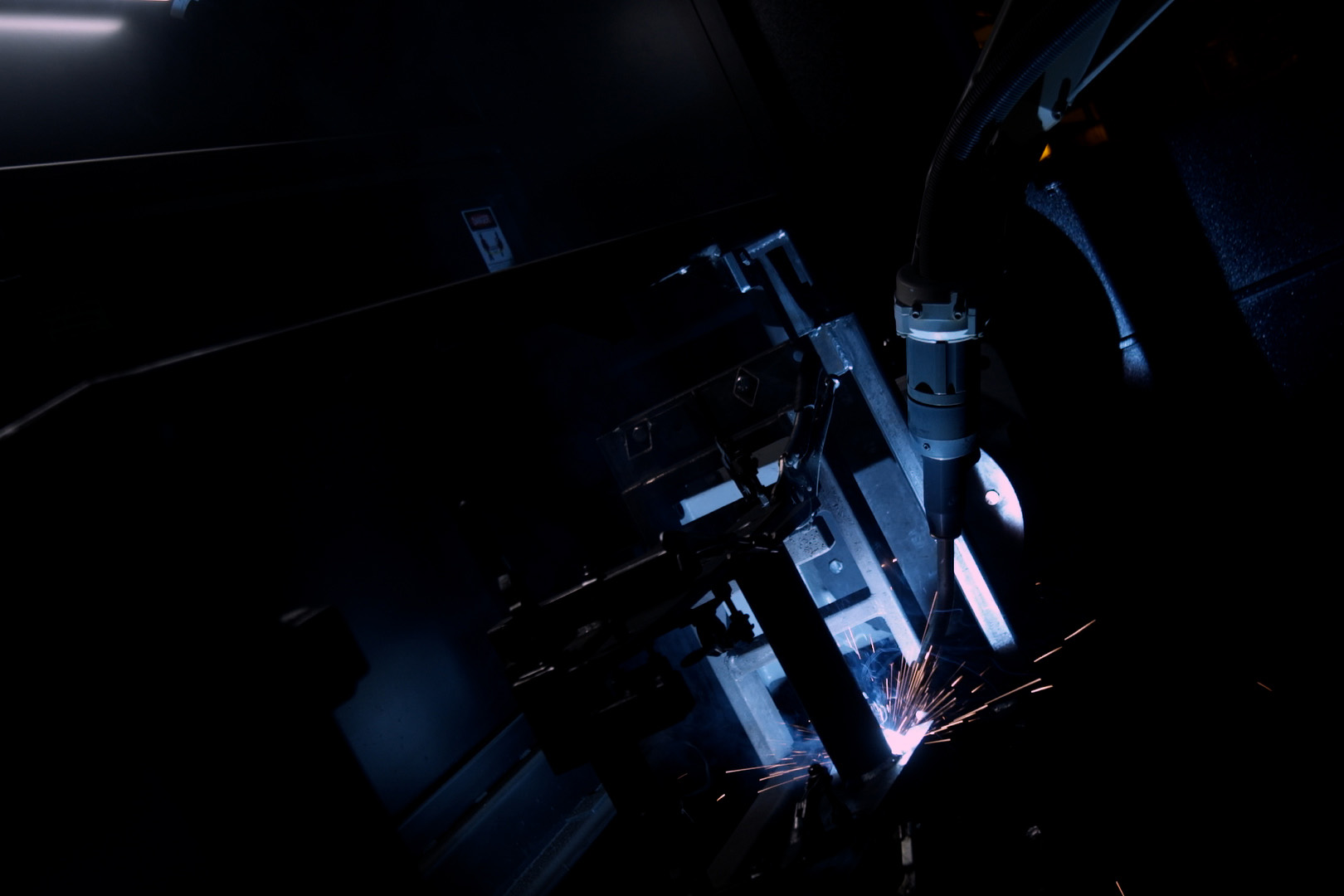

WELDING & FABRICATION

CONTACT US

WHAT OUR SHOP OFFERS

At SteinerZ, we offer flexible solutions for metal welding and the fabrication of various metal materials. We take pride in providing flexible solutions, quality craftsmanship, and shorter lead times. Each of our welders, fabricators and technicians are trained to provide accurate work in a timely manner. This is something that sets us apart from all other welding and fabrication companies in Russellville, MO.

Our facility is fully equipped to handle welding and metal fabrication jobs of various types and sizes. We have the staff, technology, and confidence to handle any challenge in the most effective and convenient way. With us, you will always get your parts on time, and on spec. We pay great attention to detail to ensure the highest quality of work.

MIG (METAL INERT GAS) WELDING

TIG (TUNGSTEN INERT GAS) WELDING

The second type of welding we offer is TIG welding, also known as GTA or Gas Tungsten Ark welding. Created by the aircraft industry to weld magnesium a few decades ago, this process involves making an arc between a base metal and a non-consumable tungsten electrode. Unlike MIG welding, this type of electrode doesn’t melt. When the arc touches the base metal, a molten weld pool is formed. A type of filler metal is fed into the weld pool, and when it melts, the welding process is complete.

Inert shielding gas is used to protect the weld pool and electrode from oxygen contamination during this entire process. There are no fluxes used, and the finished product is slag-free with all the corrosion resistance properties of its parent metal.

TRUST OUR EXPERTISE

Strategically located in central Missouri between Columbia and Lake of the Ozarks, We offer Full-service metal fabrication including, Laser Cutting, Bending, Robotic Welding and CNC Machining.

All of this is done with the highest quality & reduced lead times our clients have come to expect.

Copyright © 2024 Steinerz LLC Designed by EnergizeCreative.com